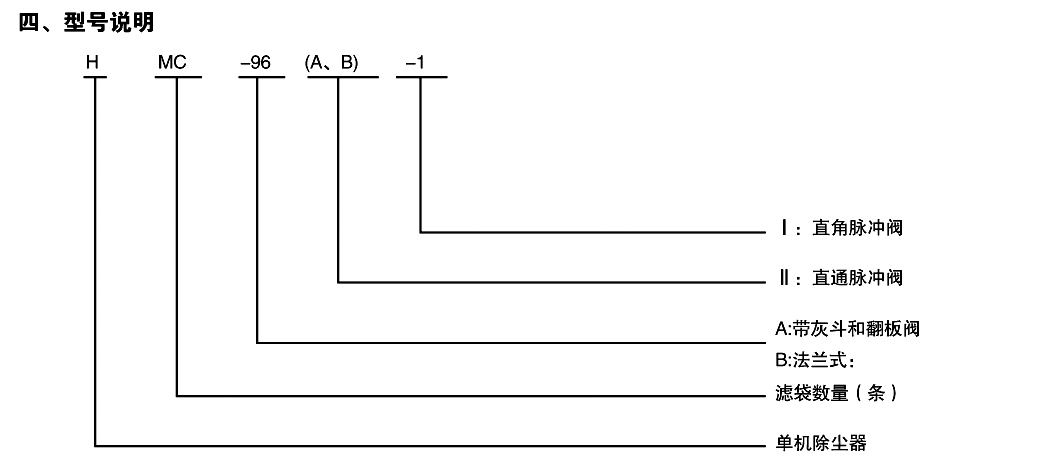

working principle

2、 Structural features

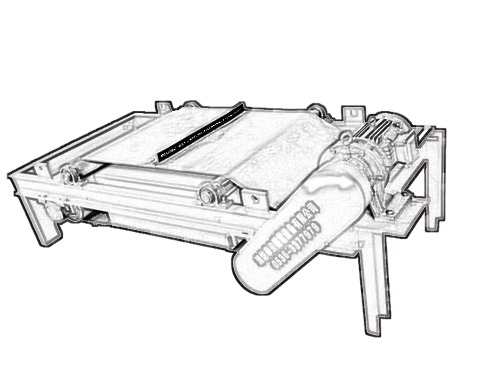

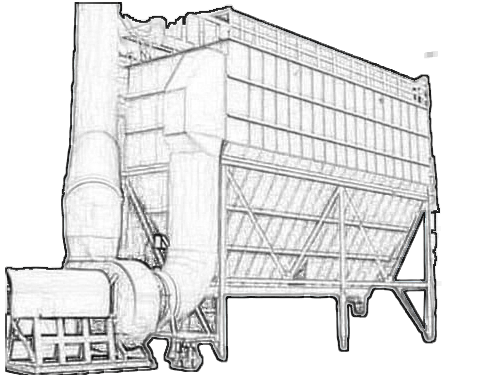

The main body of the dust remover is composed of shell, filter bag assembly, jet soot cleaning device and ash discharge device.

The shell part is composed of upper box, middle box, ash hopper and air inlet and outlet.

The filter bag assembly is composed of filter bag, filter bag frame, etc.

The soot cleaning device is composed of air bag, injection pipe, pulse valve, electromagnetic control valve and electric control instrument.

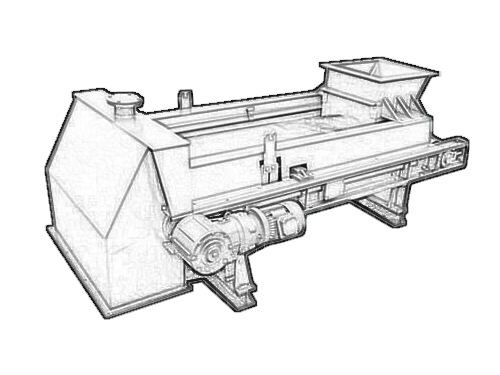

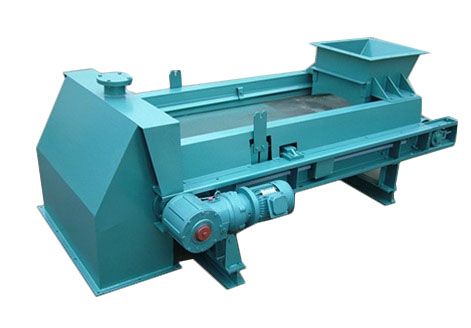

The ash discharging device is composed of motor, reducer, spiral ash conveyor and star discharge valve.

Pulse valve |, type |, adopts right angle pulse valve and type adopts blow through pulse valve, which reduces the resistance of pulse valve itself and is an ideal form of pulse injection.

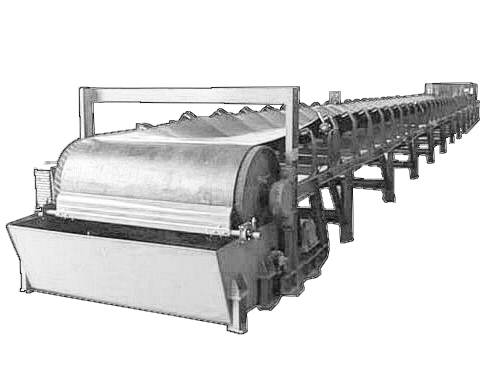

3、 How it works

The air inlet of HMC type dust remover is set on the ash hopper. When the dust containing gas enters the ash hopper from the air inlet, it first hits the baffle at the end of the air inlet pipe. Due to the inertia effect, the coarse particles in the gas directly enter the ash hopper to play the role of pre dust collection. The air flow into the ash hopper is then folded upward through the filter bag with metal framework inside. The dust is collected on the outer surface of the filter bag. The purified gas enters the cleaning room at the upper part of the filter bag room and is collected to the air outlet pipe for discharge. The indoor dust collection bags are divided into several rows, and each row of dust collection bags is cleaned according to the given time interval. When the pulse valve is opened, high pressure air is injected into the filter bag to remove the dust on the surface of the filter bag. The pulse injection width and cleaning cycle of each row of filter bags are automatically and continuously controlled by a dedicated dust cleaning program controller. The structure and working principle of the precipitator are shown in the attached figure. The dust containing gas enters the filter chamber from the ash hopper (or the lower open flange), and the coarse particles fall directly into the ash hopper or ash bin.