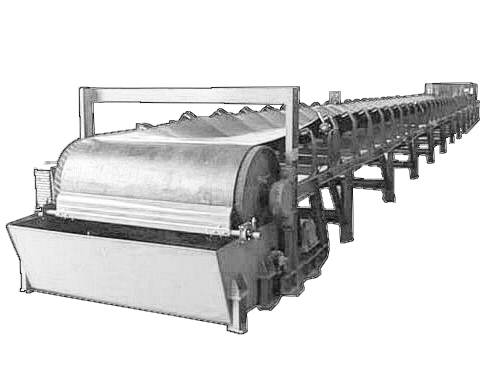

working principle

The principle is that when the ore enters the magnetic area, the strong magnetic minerals are adsorbed on the surface of the cylinder, and the weak magnetic and non-magnetic minerals are thrown away and discharged. The strong magnetic substances adsorbed on the surface of the cylinder rotate with the cylinder and are taken out of the magnetic field area and washed into the concentrate tank with flushing water to complete the separation operation.

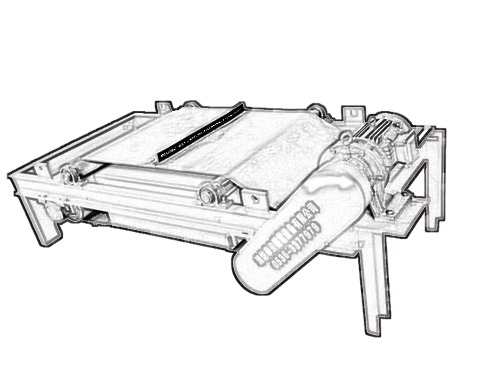

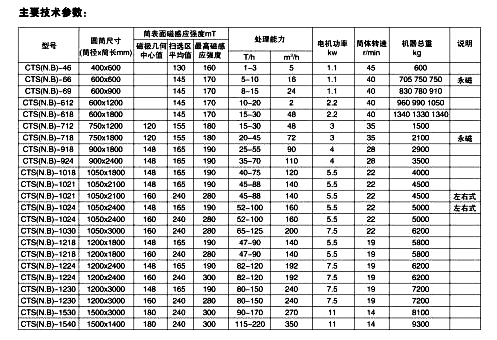

Three types of troughs can be arranged in the same diagram, namely, the forward flow channel (CTS), the counter current channel (CTN) and the semi arrival channel (CTB).

The downflow trough is used for roughing and cleaning of ore with a grain size of 6-0 mm.

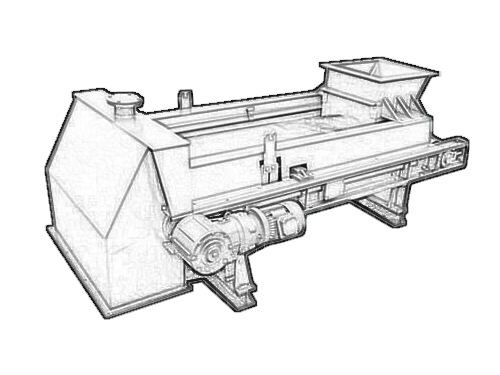

The counter current tank is suitable for roughing and scavenging of ore particle size of 0.6-0, as well as heavy medium recovery in coal preparation industry. The semi counter current trough is suitable for roughing and cleaning of ore with porosity of 0.5 - 0 mm. It is especially suitable for the cleaning of minerals with particle size of 0.15-0 mm.